-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories

- Coatings

- Fixings

- Samples

-

Resources

- Projects

- Contact

Building Beyond Zero

Sustainable building expert Chris Magwood explains how carefully chosen materials can turn buildings into carbon sinks.

Canadian Chris Magwood is a man of many hats - but all of them belong on the same rack: the one labelled sustainable building. His passion for creating buildings that help rather than hinder the Earth has resulted in the creation of a tool to help specifiers find verified low-to-no carbon materials for their projects. He explained this tool and the drive behind it at a recent webinar presented by Abodo, titled ‘Carbon Drawdown Now’.

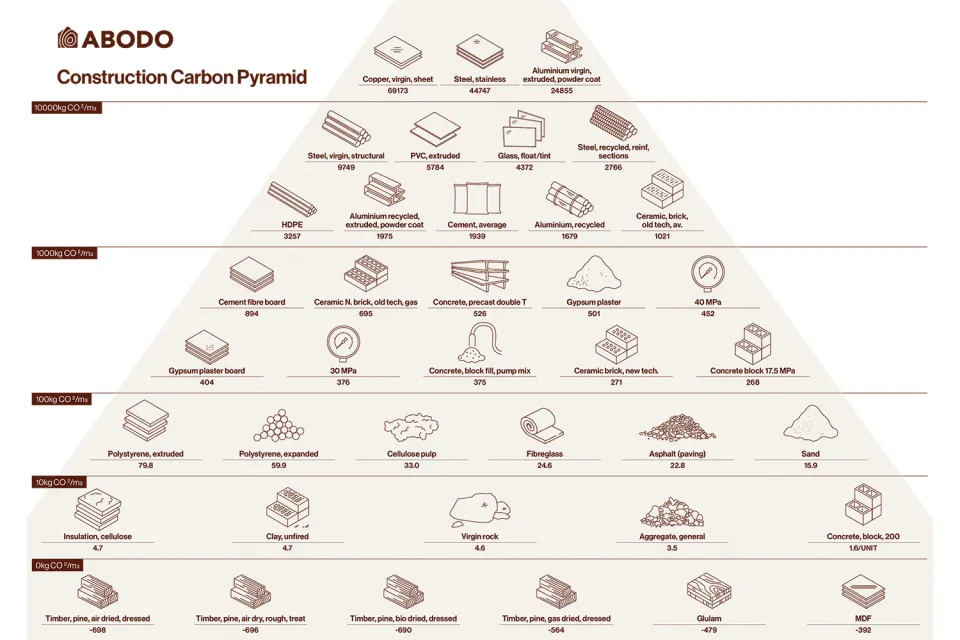

Chris Magwood’s self-proclaimed obsession with planet-friendly building began with the construction of his own straw bale house in 1998. Working on many such buildings since, and through his work as a researcher and writer, he saw the need for a simple system for ascertaining the carbon cost of materials.

Emissions from each product are calculated based on a study of Life Cycle Analysis (LCA), which looks at the emissions across each phase of a material’s life cycle, factoring in everything from the extraction of raw materials, transportation and processing, right through to the potential for replacement and repair, and the eventual demolition at end of life. LCA also informs the generation of Environmental Product Declarations, those independently verified documents that show the overall environmental impact of products such as building materials.

To test BEAM, Chris looked at 190 homes across Canada and quantified the carbon load of each based on its materials. He found that buildings created using materials with embodied carbon, such as straw or timber, contributed to the smallest carbon footprint.

“If we’re going to make a building store carbon, we want to think about keeping that carbon out of the atmosphere for the longest possible time. We realised one of the reasons buildings come down is not because they’re not structurally sound or not useful, but because someone wants to change what’s on the land,” he says.

To investigate this, Chris created the Zero House, a building that uses zero carbon, zero net energy, and generates zero toxins and zero waste - and which can be taken down, moved and rebuilt in a day, prolonging the amount of time its carbon content is retained.

Another interesting example was a building created for Trent University in Ontario. Through a careful choice of materials, Chris was able to reduce the building’s carbon footprint by 88% - and by using carbon-storing timber, the building tipped to a net carbon storage of seven tonnes.

Aside from the carbon emissions of materials, the operational emissions of a building must also be taken into account when calculating its carbon cost - and this is where passive building techniques come into play.

For some elements - Chris points to triple glazed windows as an example - the outright cost can be weighed against the long-term cost of heating and cooling a building without them. Similarly, these decisions can reduce or increase the carbon cost of the building. Chris is also quick to point out that a low carbon house does not have to look different from one that has high emissions.

“There is also no relationship between cost and carbon footprint. For instance, bricks are expensive but also high in carbon emissions,” he says.

“One of the things we’ve learned is that there’s a whole bunch of low-hanging fruit that doesn’t change the building, like going to a concrete supplier and specifying a high SCM (Supplementary Cementitious Materials) concrete. It will be just as strong and the same cost but a lower carbon footprint.”

Some materials Chris recommends for low carbon emissions and greater carbon capture are thatching, strawbale insulation, hempcrete, cellulose insulation, wood fibre boards, and, of course, FSC® certified timber products such as Abodo Vulcan.

This thermally modified, New Zealand-grown Radiata Pine is verified to store more carbon than is used in its production, as certified by the product’s Environmental Product Declaration released in 2020.

Using Abodo and other carbon storing materials, a building can become part of the solution to climate change, instead of being part of the problem - and this is sure to make Chris and his team smile.