-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories

- Coatings

- Fixings

- Samples

-

Resources

- Projects

- Contact

How Vulcan Timber Positively Impacts a Building Life Cycle Assessment (LCA)

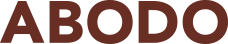

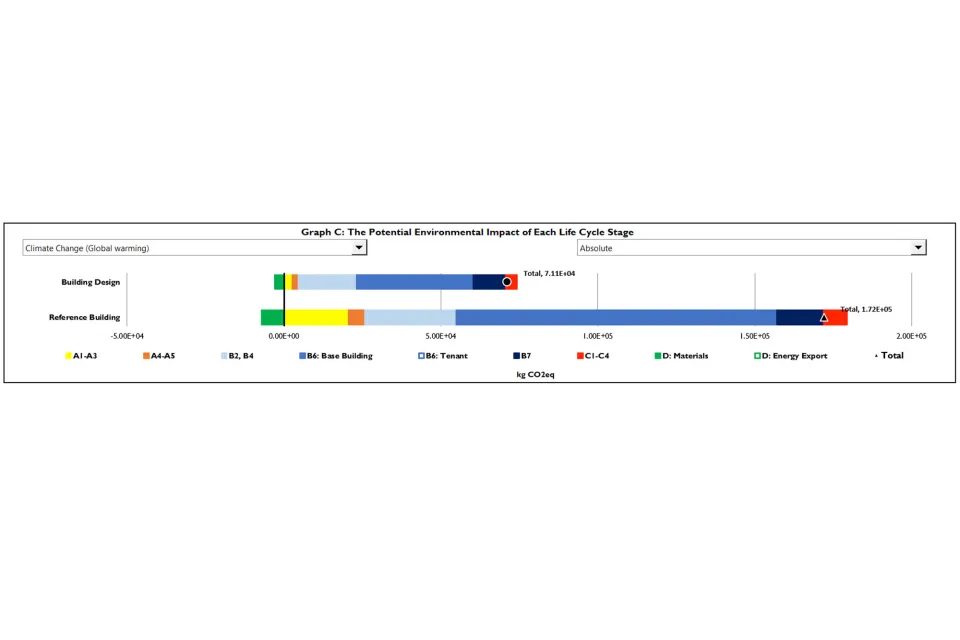

This Building Carbon Life Cycle Assessment (LCA) by Arthur Lee from Respond Architects shows the positive impact Vulcan timber can have on a home’s carbon footprint.

Queenstown-based Passive House designer Arthur Lee from Respond Architects is passionate about crafting beautiful homes that are also finely tuned machines for energy efficiency and environmental sustainability. We sat down to talk with him about the recent Building Carbon Life Cycle Assessment (LCA) he carried out on a small Queenstown cabin design, where he tested Vulcan Cladding as a potential facade material.

With a considered, energy efficient building design, the initial LCA carbon emission was less than half that of an average New Zealand building. Arthur Lee asked, how could it be better?

The case study Arthur used for this Life Cylcle Assessment (LCA) was a modest, timber framed and piled, 75m2 cabin that was designed to deliver a high level of energy efficiency. Compact, lightweight and transportable with timber linings and structure, it had a good starting point in terms of embodied carbon.

Arthur’s first step was to see how this building performed in its current state. To make these calculations, Arthur used LCA Quick, a life cycle assessment software developed by BRANZ to cover the majority of common building materials and the power grid emission factor used in New Zealand.

“The beauty of the life cycle assessment is it is one of the very few tools we have that are actually universal,” says Arthur. “If you read life cycle assessments in Europe, North America, China, New Zealand - they all share the same methodology and the same categories. And then when you report, you can have certain exclusions and inclusions, but they all follow the exact same structure. So every single life cycle assessment is comparing apples to apples, basically.”

In his initial assessment, the cabin was found to have a life cycle carbon emission less than half that of an average New Zealand building. A good result, but Arthur had hoped for more. “We were surprised since we put in a lot of effort into the energy efficiency and it’s just a small, timber cabin, why is it not better?” he says.

Replacing all profiled metal with Vulcan timber, resulted in a 10% improvement in carbon output.

Reading further into the data from LCA Quick, it was clear that the most carbon intensive material in this particular building was the steel cladding and roofing, with the second being the refrigerant used in heat pumps.

“I thought, let’s see what happens if we change all the steel to Abodo timber, including a shingled roof. I saw Daniel Gudsell’s post about how Abodo were trialling Vulcan Shingles, so I thought I would add that in!” says Arthur. “So then you have a true wooden cabin with all timber cladding and roofing. I’ve changed nothing else, just the metal to Vulcan timber. The result is that, in the product stage, it’s now net carbon negative.”

Without making any changes, the total life cycle carbon of the cabin was 71 tons, across a 90 year lifespan including construction. This consisted mostly of long term maintenance, replacement and energy use. With the Vulcan timber swapped in, the cabin now had negative embodied carbon and its life cycle carbon emissions reduced to 61 tons. The overall difference in readings was 9.8 tons of carbon, a result of more than 10%.

“With the change to Abodo, the construction of this house has embodied 2.4 tons negative carbon. This counts the carbon taken from the atmosphere and stored in the timber. The Vulcan product offsets the other necessary products, such as glazing, plus more. This is significant and it is something we can do right now as part of construction,” says Arthur.

Below are Arthur Lee’s graphs of the potential environmental impact of each Life Cycle Stage.

A happy marriage between energy efficiency and sustainably sourced building materials (such as Vulcan timber), makes for a good building, Arthur concludes.

With around two thirds of the total life cycle carbon emissions coming from operational energy use, energy efficiency remains important when speaking about carbon. Electric vehicle use is a good analogy. “Any EV has much higher embodied carbon compared to a diesel car due to the battery production, but we know it’s still a better option because the ongoing saving on fuel outweighs its embodied carbon,” says Arthur.

For buildings on the other hand, with our power grid becoming greener over time, the level of importance of embodied carbon is on the rise. With modern materials and design trends over recent years, the New Zealand building industry began to lean away from its more traditional timber buildings towards steel and concrete, a change which Arthur believes we should reverse.

“If you talk to any carbon modeler or life cycle assessment specialist, it’s pretty easy for them to agree that there is just no magic solution for concrete and steel. And as soon as a building uses a large amount of it, there is no cure for overcoming the product production embodied carbon.”

“You can easily develop a product that’s A+ for the environment but fails on social and economic benefits. One of the biggest challenges in tackling embodied carbon is that it tends to offer relatively smaller social and economic benefits. But when you add the operational carbon figures, suddenly the equation changes because a better building means people will be warm and healthy. And by the way, it’s saving energy in the long term.” Arthur goes on to add “having a holistic picture and finding the balance amongst these three factors is what a good building is about.”

While he claims not to be a numbers person, Arthur enjoys the process of creating these data models and seeing the true impact specification can have in the architectural profession.

“It’s good to see some scientific figures put together instead of just saying, okay, timber is always good,” says Arthur. “And by doing this, you really see the potential scale of impact a sustainably sourced timber product can have on a building.”