-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories

- Coatings

- Fixings

- Samples

-

Resources

- Projects

- Contact

HOLIDAY HOURS / All sample orders or enquiries made between 19 Dec to 4 Jan will be actioned from 5 Jan. Learn more here.

New Fire Retardant Regulations for External Cladding

On 1 January 2017 a restriction on the use of combustible external cladding was published as part of Amendment 4 of Acceptable Solutions C/AS2–7.

A recent amendment to the New Zealand Building Code, C Protection from Fire: C/AS2 means that the maximum height for timber cladding has been harmonised to 10m.

All cladding for buildings over 10m high requires a fire test. The test is small-scale cone calorimeter test to ISO 5660 that provides a total and peak heat release rate of the material or alternatively NFP285 full wall test may be used.

The logic is - the higher the heat release rate the more combustible the material. Timber claddings with fire retardant treatment are required to be pre-weathered according to ASTM2898 test method prior to fire testing.

A cladding system is defined as the outside or exterior weather-resistant surface of a building and this includes cladding, underlays, cavity components, windows, doors and all penetrations, flashings, seals, joints and junctions.

Critically the testing requirement applies to all components within the cladding system.

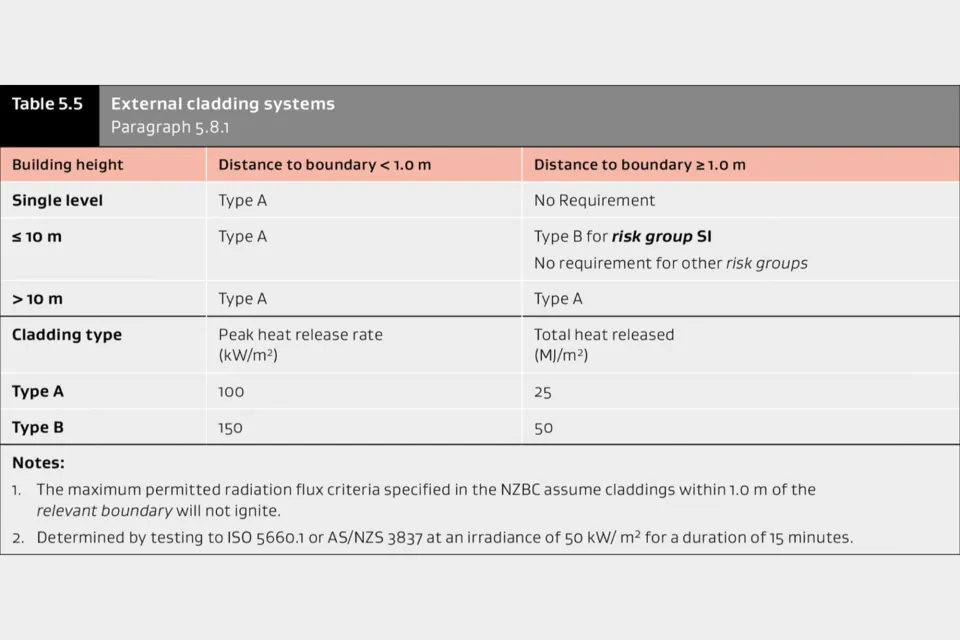

There are two types of categories for cladding material:

Cladding Type A - Peak heat release rate (kW/m2): 100 / Total heat release rate (MJ/m2): 25

Cladding Type B - Peak heat release rate (kW/m2): 150 / Total heat release rate (MJ/m2): 50

The Acceptable Solution requirements for external cladding are as follows:

Building height 0-10m - Distance to boundary <1m: Type A / Distance to boundary >1m: Type B for Risk Group SI, No Requirement for other Risk Groups

Risk Group SI is sleeping use where care or detention is provided, such as a care home or hospital.

Building height >10m - Distance to boundary <1m: Type A, Distance to boundary >1m: Type A

Non-combustible materials meet the requirements for both Type A and B without testing, for example, concrete, brick/block, ceramic tile, aluminium, glass, steel, cellulose fibre-cement products with applied finishes/coatings less than 1mm thick.

Timber products would usually not meet the above requirements without an application of a fire retardant treatment. Same would clearly apply to products that are equally or more combustible as timber, for example EPS or uPVC type products.

A link to the full published document can be found here. Contact Abodo with your project details to see if we can help meet fire compliance requirements for timber cladding, weatherboards and fascia.

Disclaimer: This article is informative only and should not be relied on for building design or compliance purposes. Always seek advice from a professional fire engineer prior to specification.