-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories

- Coatings

- Fixings

- Samples

-

Resources

- Projects

- Contact

Performance of European Thermally Modified Softwood in Australian Conditions

Increasingly thermally modified softwood products are making their way to Australian shores from Europe.

While these products may be suitable for northern European climates, they are not always suitable for Australian conditions. Some key points to note include:

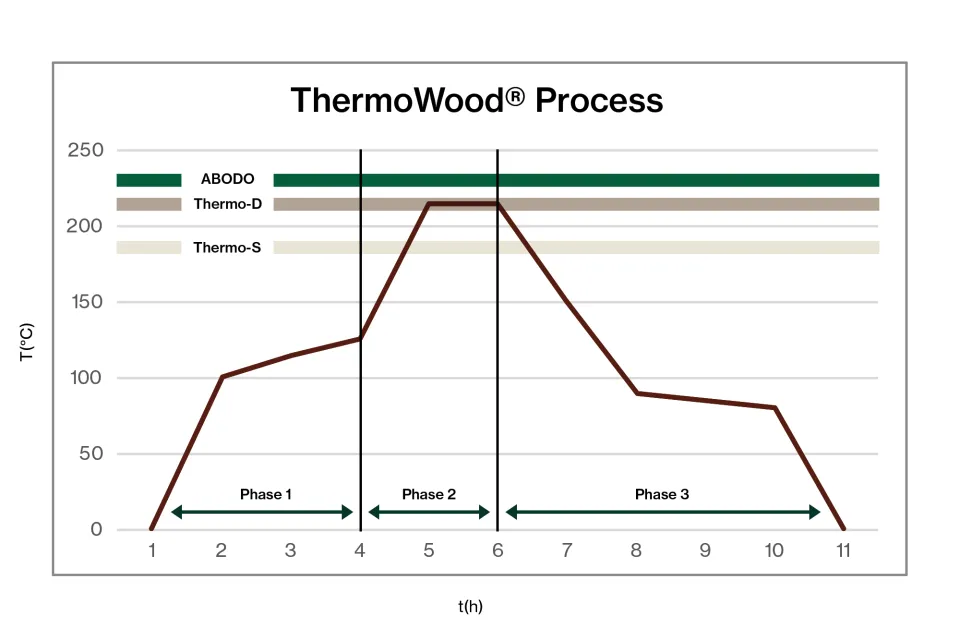

Thermal Modification Schedule

Most European manufacturers use the Thermo- D modification schedule with a maximum temperature of 212deg. Abodo has found temperatures lower than 220deg to provide insufficient protection (see link) against decay in the southern hemisphere markets.

The temperature has a direct relationship with durability and stability, this is why Abodo modify at 230°C rather than lower temperatures. Softwoods modified at 212°C will be less stable, and prone to premature decay in wetter climes.

Termite Protection

Despite some manufacturer claims, imported European thermally modified softwood products have little to no termite protection when exposed to Australian termites.

Termite field testing in Australian conditions has indicated significant termite damage to thermally modified pine. For guaranteed protection against termite attack, some insecticide treatment is required.

Abodo’s Vulcan range of timbers are H3 treated to Australian standard AS 1604.1: 2012, and have been proven to be resistant to Australian termites.

Compliance to Australian Building Code

Thermally modified softwood products may not comply with the Australian building code – typically softwood cladding should be preservative treated for compliance. Any imported thermally modified softwood should be assessed against the requirements of the Australian Building Code prior to use.