-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories

- Coatings

- Fixings

- Samples

-

Resources

- Projects

- Contact

Sustainability Matters at Abodo

At the core of what we do, Abodo is taking action to create a better tomorrow.

Abodo has a commitment to lifetime beauty and meeting today's increasing needs without disadvantaging future generations.

One of our core values is walking the talk. Whilst we recognise there is always more we can do, here are three main areas we have already put sustainability into action.

- Our Product Approach

- Circular Economy Education and Community

- Better Business

1. Our Product Approach

Baked into our carefully crafted timber and eco-system is a focus on a long term sustainable supply of Forest Stewardship Council® (FSC®) certified, rapidly renewable log stock, along with a sensitivity to avoid harmful materials in our manufacturing process and contributing to a lower carbon footprint by localising our log processing.

Our Environmental Product Document (EPD) released in October 2020 verifies that Vulcan timber stores more carbon than is used in its production, meaning the built environment industry can capitalise on carbon storage and wellbeing benefits.

Localised Log Processing

We choose only the highest quality logs, which are then sawn in close proximity to the forestry plantation.

This means that transport-related emissions are minimised and operational efficiencies are maximised.

Thermal Modification Using Heat + Steam

Thermal modification uses steam and high temperatures in excess of 190 degrees Celsius, dramatically increasing the durability and stability of the wood.

This is achieved without the use of wood preservatives or chemicals of any type. Together with our sawmill partners, we have co-invested in three (soon to be four) thermal modification kilns.

Environmental Product Declaration (EPD)

Each square metre of Vulcan Cladding stores 7.56kg+ of carbon. That makes an important difference to the embodied carbon in your building.

2. Circular Economy Education and Community

Our commitment to a better carbon built environment and sustainable future has extended to the building of Cardrona Cabin, to demonstrate significant carbon storage benefits to be gained through the use of timber.

We have also developed a building materials carbon pyramid education tool, collaborate with architectural education institutes, and sponsor like-minded sustainable causes.

Reducing Carbon Footprint Case Study: Cardrona Cabin

Abodo’s award-winning Cardona Cabin makes extensive use of Vulcan timber in the interior and exterior, storing considerable amounts of CO2e.

Over nine tonnes of carbon are stored in the Vulcan timber elements alone, dramatically offsetting the small amounts of concrete and structural steel used in the building.

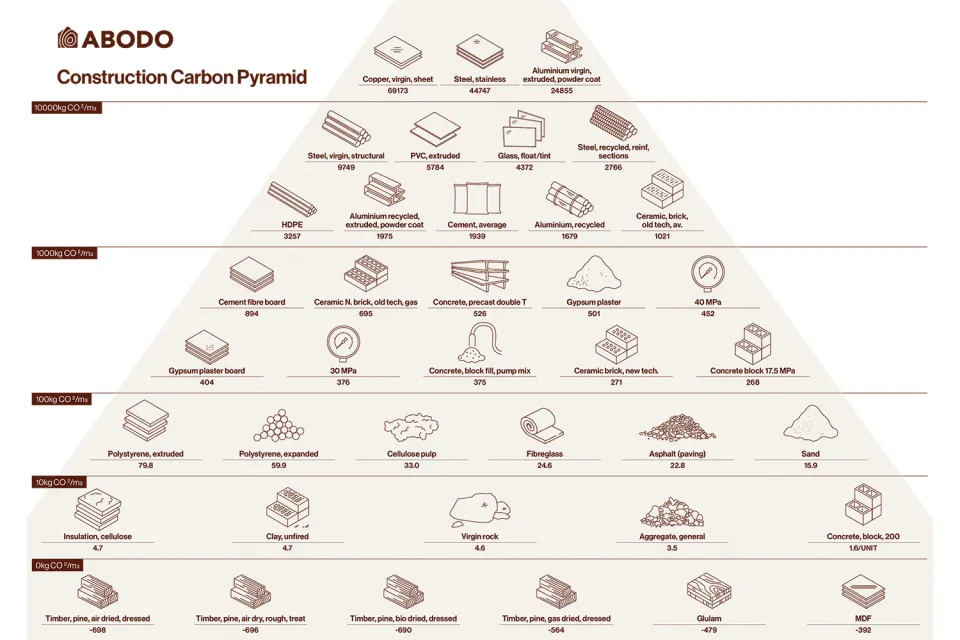

Carbon Pyramid

We created this pyramid to help people quickly compare the carbon storage of different materials, so they can make more sustainable choices.

Materials that store less carbon are at the top of the pyramid, and materials which store more at the bottom.

Venice Biennale Collaboration

Abodo also sponsored the Venice Biennale; a collaboration between staff at the University of Auckland School of Architecture and Planning and Andrew Barrie, the installation explores the use of timber as an innovative building material that is both sustainable and strong.

Created for the 17th Venice Biennale, the design utilises 436 individual pieces of our Vulcan timber.

Architecture Student Community Project

We provide offcuts of our timber, free of charge, for architectural students to unleash their creativity and learn the benefits of working in a circular economy.

One example is this bike pod created by Unitec School of Architecture students – encouraging sustainable practices in more ways than one.

Sustainable Sponsorships

Abodo sponsors projects that support regenerative, sustainable initiatives, for a better tomorrow.

These include:

Donating to causes such as Trees that Count, Sustainable Coastlines, Clean State and Greening Australia as part of our Christmas 2021 gifting.

Sponsoring the Esk Valley nursery build, in partnership with Pan Pac, one of Abodo’s key forestry partners. The nursery will produce 10,000 natives per year that will all be used for riparian planting and ecosystem enhancement.

3. Better Business

Taking action within the day-to-day business operation of Abodo to be more sustainable, not only benefits the bottom line, but has wellbeing benefits for our people and contributes to having a lighter carbon footprint in our manufacturing processes.

We’re growing our e-fleet, recycling materials and using solar powered energy where we can.

E-Fleet: E-Bikes, EV Forklifts & Cars

Three e-bikes are being used by the Abodo Mangere Warehouse team for travel to and from work. This is also in an effort to reduce the number of cars on the road, and to help staff reduce travel costs.

Barney is one of the four electric forklifts we run at Abodo Mangere. A good deal of the electricity generated to run Barney is from solar panels on our roof. Having made the switch from LPG over five years ago we will never go back.

All new additions to the Abodo fleet are EV, including a recent pool car for shared staff use. If staff have their own EV, they are encouraged to charge the vehicle while it’s parked at the office – to utilise Abodo’s solar generated electricity.

Recycling Materials – Timber Offcuts & Packaging

The Abodo Mangere team are now recycling our own waste cardboard into protective packaging. Samples and accessories are now protected with cardboard instead of plastic.

We are also sharing a little bit of wood love in every sample box sent within New Zealand. In a co-lab with Unitec School of Architecture we have upcycled our Vulcan Panelling offcuts into a little wood heart, a perfect demonstration of love for rapidly renewable wood.